integrated smart cabinet manufacturer

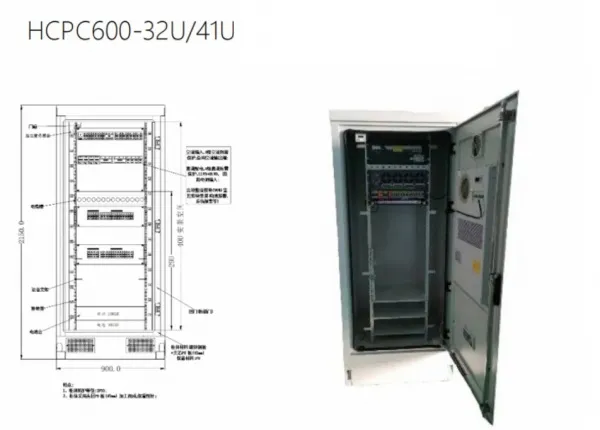

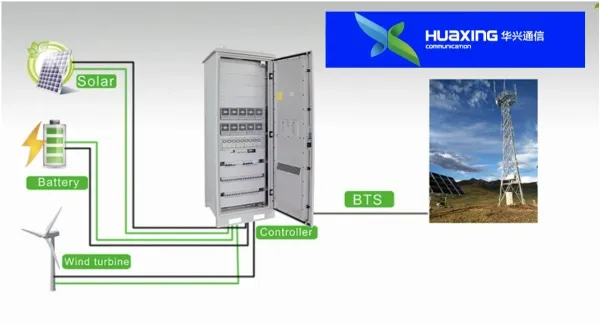

An integrated smart cabinet manufacturer represents the pinnacle of modern industrial innovation, combining advanced automation technology with precision engineering to produce state-of-the-art electrical distribution solutions. These manufacturers utilize cutting-edge production facilities equipped with smart manufacturing systems, quality control protocols, and intelligent assembly lines to create custom-designed electrical cabinets. Their manufacturing processes incorporate real-time monitoring systems, automated testing equipment, and advanced diagnostic tools to ensure each cabinet meets stringent quality standards. The facilities typically feature climate-controlled environments for optimal component assembly and testing, while specialized software systems manage inventory, production scheduling, and quality assurance protocols. These manufacturers employ sophisticated design software for 3D modeling and simulation, allowing for precise specifications and reduced production errors. Their integrated approach encompasses everything from initial design consultation to final testing and certification, ensuring a seamless manufacturing process. The production line includes advanced metal fabrication equipment, automated powder coating systems, and precision assembly stations, all connected through an intelligent manufacturing execution system. This comprehensive manufacturing ecosystem enables the production of smart cabinets that feature remote monitoring capabilities, integrated safety systems, and efficient power distribution solutions, meeting the diverse needs of industrial, commercial, and utility applications.